18 Years Factory Sino Table Surface Grinder Machine - Precision CNC Forming Surface Grinder 450CNCS – BiGa

18 Years Factory Sino Table Surface Grinder Machine - Precision CNC Forming Surface Grinder 450CNCS – BiGa Detail:

Standard accessories:

Magnetic Chuck 1 pcs

Grinding Wheel 1 pcs

Wheel dresser with diamond 1 pcs

Wheel flange 1 pcs

Tool box 1 pcs

leveling screw and plates 1 pcs

flange extractor 1 pcs

Tool box with adjusting tool 1 pcs

wheel balancing arbor 1 pcs

coolant system 1 pcs

wheel balancing base 1 pcs

Linear scale (1 um 2 axis cross/vertical)

Precision and Stabilization

Special designed CNC controller with best grinding quality could easily meet your requirement.

Steady

High rigid machine structure is to ensure lasting accuracy of machine and high stability in the state of regrinding.

Magnetic paper belt filter flushing device

Avoiding iron powder hurts the workpiece.

Ball Screw of Y Axis

Feed on y axis is driven by ball screw of High precision which is added with telescopic protective cover to protect it and to ensure optimal service life.

The ball screw is lubricated by sealed lubrication, would not need lubrication separately.

Precise spindle

Spindle and motor (V-3 degree) are all driven directly. Spindle is made of super precise (P4-degree) double roller bearing to ensure best grinding rigidity and quality.

MACHINE FEATURES

Precision

• Worktable accuracy assurance (3um error of height on six trials of grinding)

• Min. Tool feed unit 1 um on all sides

• 3u Using C3 degree roller ball screw on Y axis with 3 um repeat positioning accuracy.

• Z and Y axes have higher precision glass linear scale.

Spindle and Motor

• Z and Y axes are drove by AC servo motor.

• 2HPV 3 spindle and motor 2HP.V3

• Direct precision spindle, Front bearing of spindle use P4 degree roller double bevel bearing.

Auto lubrication system

It is a loop type Auto lubrication system. Lubricant can automatically lubricate for all screws and slide rail to greatly reduce wear level of slide rail.

Cross worktable

Cross worktable has advanced hydraulic loop system. Worktable could reach the Min. Vibration when it reverse at both ends. Its speed is 1 25m/min. Build-in switch could ensure safe operation.

Bottom bed and slide rail

Double “V” on the Y axis, a “V” and a flat on the X axis with wear-resistant plate. TURCITE ,are hand scraped and rail are all hard rail.

Integrated bottom bed casting is made of FC300 high degree cast iron, which could keep its indeformable after quenching treatment.

CNC controller CNC

Easy-to-use CNC controller automatically grind the bottom and side of work piece and bevel grinding wheel automatically compensate to largely improve work eficiency and reduce labour cost.

MULTIFUNCTIONAL GRINDING RANGE

Surface Grinding

Cut Full of Grinding

Serpentine Grinding

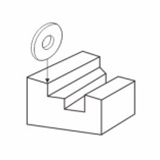

Non- equidistant, different depth tankful Step Grinding

Slope grinding

SPECIFICATIONS

| Model | Unit | 450CNCS | ||

| Capacity | Max.grinding area | mm | 450×150 | |

| Distance from spindle centre to work table | mm | 400 | ||

| Work table | Work table size(L”W) | mm | 450×150 | |

| Xaxis travel | mm | 550 | ||

| Yaxis travel | mm | 180 | ||

| T slot(S*N) | mm*n | 17×1 | ||

| Feed | Work table cross movement |

Hydraulic dre speed | m/min | 1-25 |

| Handwheel per revo luton | mm | 69 | ||

| Saddle Longitudinal movement |

Manual Handwheel per revolution | mm | 5 | |

| MPG Electronic handwheel MPG(per scale) (X 1, X 10, X 100) | mm | 0.001,0.01,0.1 | ||

| Manual Handwheel per revolution | mm | 5 | ||

| Manual Handwheel per scale | mm | 0.02 | ||

| Spindle head vertical movement |

Manual Handwheel per revolution | mm | 1 | |

| MPG Ele cronic handwheel MPG(per scale) (X 1, X 10, X 100 | mm | 0.001,0.01,0.1 | ||

| Manual Handwheel per scale | mm | 0.005 | ||

| Automatic vertical feed |

Each amount of feed(rough/precise) | mm | 0.001-0.099 | |

| Total amount of feed | mm | 0.001-999.999 | ||

| Total amount of fine grinding | mm | 0.001-0.099 | ||

| Zero grinding | times | 0-9 | ||

| Spindle and Grinding Wheel |

Spindle HP | HP | 2 | |

| Spindle speed(50Hz/60H | rpm | 2850/3600 | ||

| Grinding wheel Size(OD*W*ID) | mm | 180×13×31.75 | ||

| Motor | Oil pressure | HP | 2 | |

| Longitudinal servomotor | W | 750 | ||

| Vertical servomotor | W | 400 | ||

| Machine Size(L*W*H) | cm | 220×130×200 | ||

| Packing Size(L*W*H) | cm | 200x120x220 | ||

| Machine Weight | Kg | 1000 | ||

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for 18 Years Factory Sino Table Surface Grinder Machine - Precision CNC Forming Surface Grinder 450CNCS – BiGa , The product will supply to all over the world, such as: South Africa, Brazil, Puerto Rico, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!