China wholesale Die Sinking Edm Machine - OPEN TYPE FIBER LASER CUTTING MACHINE – BiGa

China wholesale Die Sinking Edm Machine - OPEN TYPE FIBER LASER CUTTING MACHINE – BiGa Detail:

| Type | RX1530 | RX1540 | RX2040 |

| MaxcuttingsizeLxW(mm) | 3000×1500 | 4000×1500 | 4000×2000 |

| Workpiecemaxheight(mm) | 90 | 90 | 90 |

| Xaxis | 3050 | 4050 | 4050 |

| Effectivetravel(mm) Yaxis | 1550 | 1550 | 2050 |

| Zaxis | 100 | 100 | 100 |

| Acceleratedspeed(G) | 1 | ||

| Laserpower(W) | 500/700/1000/1500/2000/4000W | ||

| Powerconsumptionofthe machinetool(kw/h) |

4.85 | 4.85 | 4.85 |

| Protectionlevel | ip54 | ||

| Machineweight(KGS) | 4350 | 5450 | 6300 |

Technical

| Style | 3015/4015/6020/8020 |

| Working area | 3000*1500mm/4000*2000mm/6000*2000mm/8000*2000mm |

| Laser power | 1500w to 8000w |

| Laser wavelength | 1060nm-1080nm |

| Cutting speed | 0-60m/min |

| Gross power | 20kw-30kw |

| Positioning accuracy | ±0.05mm/m |

| Repositioning accuracy | ±0.03mm |

| Max velocity of movement | 130m/min |

| Cooling model | Water-cooling |

| Supply power | 3 phase/380V/50HZ |

|

Carbon Steel |

0.4-5 |

0.4-6 |

0.4-8 |

0.4-10 |

0.4-12 |

0.4-14 |

0.4-40 |

|

Stainless Steel

|

0.4-12 |

0.4-14 |

0.4-16 |

0.4-20 |

0.4-22 |

0.4-24 |

0.4-50 |

|

Aluminum |

0.4-3 |

0.4-4 |

0.4-6 |

0.4-8 |

0.4-10 |

0.4-12 |

0.4-35 |

|

Brass |

0.4-3 |

0.4-3 |

0.4-3 |

0.4-8 |

0.4-10 |

0.4-10 |

0.4-20 |

|

Fiber Power

|

1000W |

1500W |

2000W |

3000W |

4000W |

6000W |

12000 |

Fiber laser cutting machine equipment can meet the needs of types of sheet metal parts production, except they are equipped with advanced fiber optic laser cutter.

High-performance servo transmission equipment, imported gear rack and linear guide, also adopted the Harley laser independent research and development of aluminum alloy extrusion bar, gantry lathe bed, to ensure that the equipment of high speed, extremely precision,

Maximum simultaneous positioning speed: 160m/min

Quick and easy installation

Up to 300% faster cutting

High wall plug efficiency (>30%)

Feature

Gantry and double-driven structure of the machine features high rigidity and steady movement, Steel-weld machine frame gets annealing treatment with constant accuracy. Fiber optic laser cutting machine features high electro-optic transfer efficiency ,fast cutting ,maintenance-free, powerful function ,high stability. German imprecision rack and pinion ensures high positioning accuracy.

Stable and reliable light path system and control system

Imported original fiber laser generator with great and stable performance to have lifespan over 100,000 hours

High cutting quality and efficiency with cutting sped up 25 m /min and beautiful, smooth cutting edge

German high performance reduced ,gear and rack, guide rail and ball screw to guarantee stable running of X axis and Y axis

High efficiency and low operating cost for steel plate

Detail

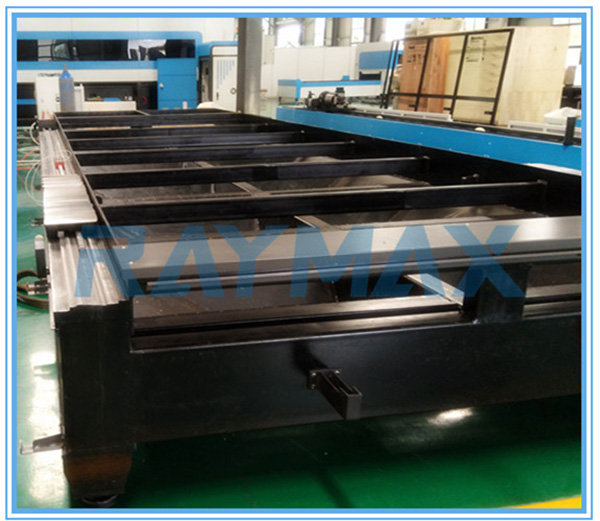

1. Steel lathe bed, 2 tempering process

2. The structure adopts industrial heavy steel structure, under heat treatment, suffers lower temperature tempering and annealing, won’t deform after long time use.

3. Flake graphite cast iron with a minimum tensile strength of 200 MPa.

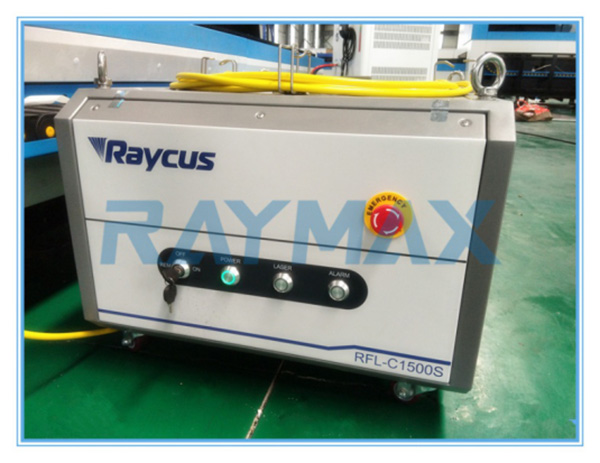

Raycus Laser Source :

Fiber laser metal cutting machine is compact in structure, stable in performance and widely used, fiber laser metal cutting has high photoelectric conversion efficiency, good beam quality and low maintenance cost, (The Germany PG Laser source is optional).

The CNC laser cutting machine gantry structure under the dual drive, linear guide and rack pair inclined installation, the stress state is more reasonable, the movement is more stable.

Cast Aluminum beam

The cast aluminum beam, Zhongrui cnc fiber laser cutting machine with light weight, good dynamic response, faster acceleration, better comprehensive cutting effect

Double temperature double control system

Fiber laser cutting machine above 500W need to be equipped with a fiber laser chiller. The higher the power, the higher the cooling capacity of the fiber laser chiller.

Because the laser body and the lens need to be cooled inside the fiber laser, a dual-temperature dual-control chiller can be used to simultaneously cool the laser body and lens.

Swiss Raytools laser cutting head

1. Two of the adjustment,focusing CAM structre, can match various QBH with laser.

2.Laser cutting head lighweight design, automatic continuous focus fuction, which can automatically monitor the pressure, temperature and pollution inside the lens.

3.Laser head Automatic focusing.

quickly change the focusing mirror of different focal lengths, adapt to a variety of power processing, to meet the cutting of different thickness plates.

4. Fast and accurately focus work more time-saving and better.

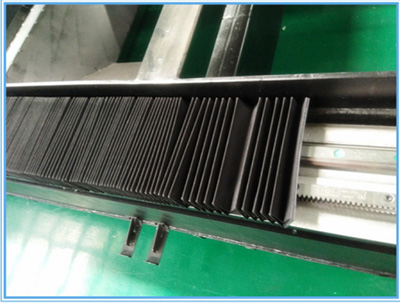

Transmission system

Excellent quality Gear-rack and liner guide rail which with Taiwan imported brand,ensure high precision and speed, and equipped with Dustproof device

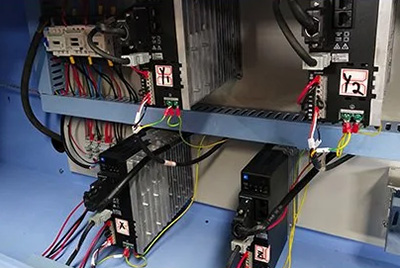

Yaskawa Servo Moto

1. Accuracy: realizes closed-loop control of position, speed and torque; overcomes the problem of stepping motor out of step;

2. Rotating speed: high speed performance, general rated speed can reach 2000~3000 rpm;

3. Adaptability: high strong anti-overload capability, load three times the rated torque, suitable for occasions with transient load fluctuations and fast start required

4. Stable: smooth operation at low speed

Driver system Japanese servo motor drive,high precision, high speed,high torque,stable and durable performance.

CNC controller

With the professional automatci typeseting software ,the cutting plate availability increase 1%-5%,cutting productivity 10%-30%, significantly improve the cut quality, process data management,data collection and statistics and other data management fnctions, visualization integrated interface, simple operation, easy to learn.

General Features:

300% faster cutting speed

70% lower electricity consumption

35% photoelectric conversion rate

Lower gas consumption

Higher cutting efficiency

Flexible beam working path

High optical quality

Compact Size

Maintenance free

Product detail pictures:

Related Product Guide:

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for China wholesale Die Sinking Edm Machine - OPEN TYPE FIBER LASER CUTTING MACHINE – BiGa , The product will supply to all over the world, such as: Macedonia, Johor, azerbaijan, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!