ELECTROHYDRAULIC SERVO CNC PRESS BRAKE

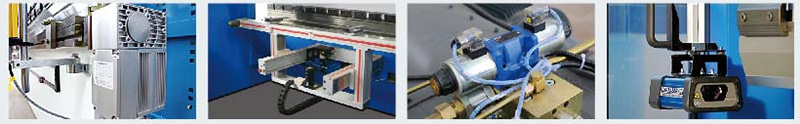

Standard Configuration

Y1 and Y2 synchronize press brake

Adjustable finger stop and front support

X axis backguage by servo motor with accuracy +0.1mm

Japan fast clamp for top punches

DELEM DA66T 3D graphic operator control

Hydralic or mechanical crowning optional

Germany Bosch Rexroth closed loop electrohydraulic system

CE safety crtifications

DA52S

●8" broadband color display,

●Max 4-axis control(Y1, Y2, X,R,V)

●266MHZ processor, memory capacity of 64M

●Die library, 30 upper dies, 30 lower dies

●USB memory interface, RS232 interface

●Micro switch panel, data editing

●Automatically calculate the bending pressure and

die safety region

DA58T

●2D graphical touch screen pragramming

●15 high resolution colour TFT

●Bend sequence calculation, crowning control

●Servo and frequency inverter

●Advanced Y-axis control algorithms for

closed-loop as well as open-loop

valves. USB, peripheral interfacing

DA66T

●2D Touch Graphics programming, 3D product

figure analog display,

●17 high-resolution

TFT color screen

●◆Full-set Windows application package

●Compatible with DELEM modular structure

●USB Peripheral interface

●Angle-detecting sensor interface

Technical Specifications

|

Model |

BendingPressure(Kn) |

Bending Lenqth(mm) |

Coumn Distance(mm) |

Throat Depth (mm) | Slider Stroke (mm) |

Max Opening Height (mm) |

Y1,Y2-axis Down Speed (nw/sec) |

Y1,Y2-axk Back Stroke Speed (mm/sec) |

Y1,Y2-axts Precision (mm) |

X-ais Max. Distance (mm) |

| 63T/2500 | 630 |

2500 |

1900 |

350 |

170 |

380 |

150 |

150 |

0.01 |

500 |

| 100T/3200 | 1000 |

3200 |

2700 |

400 |

200 |

420 |

150 |

150 |

0.01 |

500 |

| 125T/3200 | 1250 |

3200 |

2700 |

400 |

200 |

420 |

150 |

150 |

0.01 |

500 |

| 160T/3200 | 1600 |

3200 |

2700 |

400 |

200 |

420 |

150 |

150 |

0.01 |

500 |

| 200T/3200 | 2000 |

3200 |

2700 |

400 |

200 |

420 |

150 |

150 |

0.01 |

500 |

| 250T/3200 | 2500 |

3200 |

2700 |

400 |

200 |

420 |

150 |

150 |

0.01 |

500 |

| 300T/3200 | 3000 |

3200 |

2700 |

400 |

200 |

420 |

150 |

150 |

0.01 |

500 |

| 400T/4000 | 4000 |

4000 |

3500 |

400 |

320 |

420 |

150 |

150 |

0.01 |

500 |

| 500T/6000 | 5000 |

6000 |

4900 |

500 |

320 |

600 |

150 |

150 |

0.01 |

800 |

| 600T/6000 | 6000 |

6000 |

4900 |

500 |

320 |

600 |

150 |

150 |

0.01 |

800 |

| 800T/6000 | 8000 |

6000 |

4900 |

600 |

400 |

600 |

150 |

150 |

0.01 |

800 |

| 800T/8000 | 8000 |

8000 |

5900 |

600 |

400 |

600 |

150 |

150 |

0.01 |

800 |

| 1000T/6000 | 10000 |

6000 |

4900 |

600 |

400 |

600 |

150 |

150 |

0.01 |

800 |

| 1000T/8000 | 10000 |

8000 |

6900 |

600 |

400 |

600 |

150 |

150 |

0.01 |

800 |

| 1W0T/10000 | 10000 |

10000 |

8000 |

600 |

400 |

600 |

150 |

150 |

0.01 |

800 |

|

Model |

Workpiece Linear Degree |

Rear Gauge Preciswn |

Sliding Front Supporting Arms (pcS) |

Bad

Stoppet (pcS) |

V-axis Crowning |

CNC Control Aies |

Main Motor W |

Lenth'Width* Height (mm) |

Weight |

| 63T/2500 | ≥0.3mm/m | 0.05mm |

2 |

2 |

Hydraulic |

Y1+Y2+X+V |

5.5 |

3100*1450*2050 |

5.8 |

| 100T/3200 |

≥0.3mm/m |

0.05mm |

2 |

3 |

Hydraulic |

Y1+Y2+X+V |

7.5 |

3500*1580*2400 |

8.5 |

| 125T/3200 |

≥0.3mm/m |

0.05mm |

2 |

3 |

Hydraulic |

Y1+Y2+X+V |

11 |

3500*1580*2400 |

9.5 |

| 160T/200 | ≥0.3mm/m | 0.05mm |

2 |

3 |

Hydraulic |

Y1+Y2+X+V |

11 |

3500*1650*2500 |

11 |

| 200T/3200 | ≥0.3mm/m | 0.05mm |

2 |

3 |

Hydraulic |

Y1+Y2+X+V |

15 |

3500*1680*2550 |

14 |

| 250T/3200 | ≥0.3mm/m | 0.05mm |

2 |

3 |

Hydraulic |

Y1+Y2+X+V |

15 |

3500*1700*2600 |

15.5 |

| 300T/3200 |

≥0.3mm/m |

0.05nini | 2 | 3 |

Hydraulic |

Y1+Y2+X+V |

22 |

3500*1800*2730 |

16.8 |

| 400T/4000 | ≥0.3mm/m | 0.05mm |

2 |

4 |

Mechanical |

Y1+Y2+X+V |

30 |

4000*2450*3500 |

31 |

| 500T/6000 |

≥0.3mm/m |

0.05mm |

2 |

6 |

Mechanical |

Y1+Y2+X+V |

37 |

6500*2810*4500 |

53 |

| 600T/6000 | ≥0.3mm/m | 0,05mm | 2 | 6 |

Mechanical |

Y1+Y2+X+V |

45 |

6500*2910*5100 |

68 |

| 800T/6000 | ≥0.3mm/m | 0.05nm |

2 |

6 |

Mechanical |

Y1+Y2+X+V |

55 |

6500*2950*5300 |

90 |

| 800T/8000 |

≥0.3mm/m |

0.05mm |

2 |

8 |

Mechanical |

Y1+Y2+X+V |

55 |

8500*2950*5900 |

120 |

| 1000T/6000 | ≥0.3mm/m | 0.05mm |

2 |

6 |

Mechanical |

Y1+Y2+X+V |

2*37 |

6500*3000*5600 |

100 |

| 1000T/8000 |

≥0.3mm/m |

0.05mm |

2 |

8 |

Mechanical |

Y1+Y2+X+V |

2*37 |

8500*3000*6100 |

130 |

| 1000T/10000 | ≥0.3mm/m | 0.05mm |

2 |

10 |

Mechanical |

Y1+Y2+X+V |

2*37 |

10500*3000*5850 |

150 |