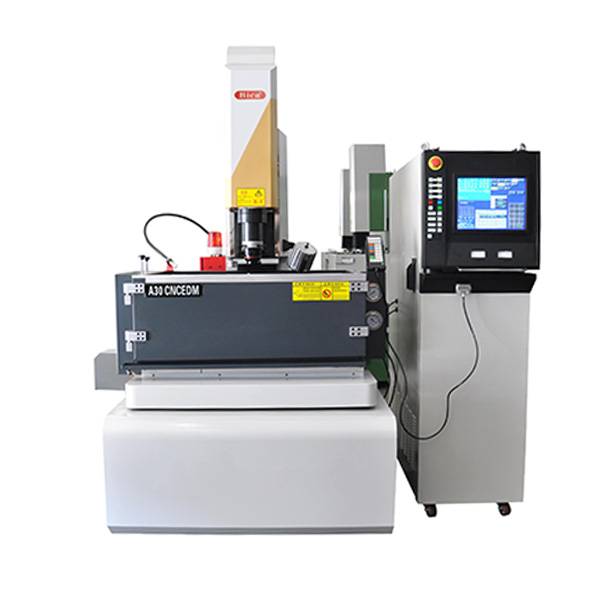

Europe style for Edm Wire Cut Machine - Taiwan quality Chinese price MV855 Machine Center – BiGa

Europe style for Edm Wire Cut Machine - Taiwan quality Chinese price MV855 Machine Center – BiGa Detail:

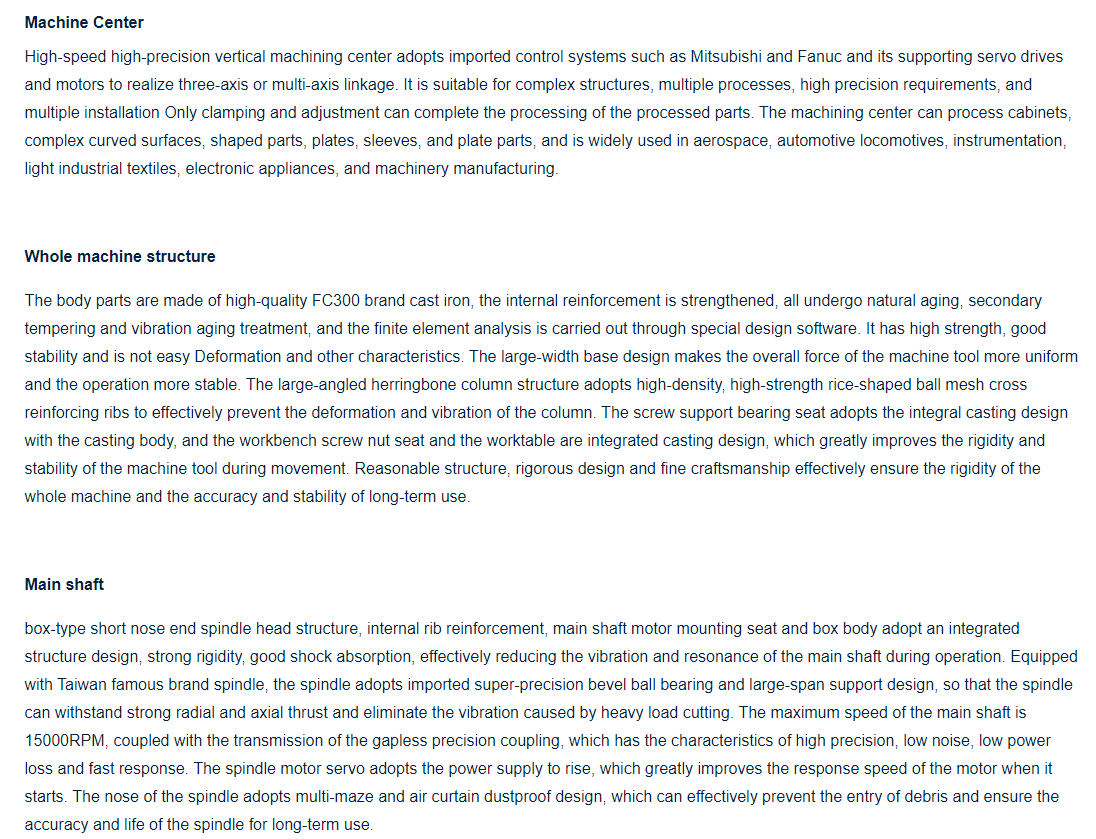

Processing size

| Model | Unit | MV 855 |

| Work table | ||

| Table size | mm(inch) | 1000×500(40×20) |

| T—solts size( solt number x widthx distance) | mm(inch) | 5×18×110(0.2×0.7×4.4) |

| Maximum load | Kg(lbs) | 500(1102.3) |

| Travel | ||

| X-axis travel | mm(inch) | 800(32) |

| Y—axis travel | mm(inch) | 500(20) |

| Z—axis travel | mm(inch) | 550(22) |

| Distance from Spindle nose to table | mm(inch) | 130-680(5.2-27.2) |

| Distance from spindle center to column surface | mm(inch) | 525(21) |

| Spindle | ||

| Spindle taper | type | BT40 |

| Spindle Speeds | r.p.m | 10000/12000/15000 |

| Drive | type | Belt-tvpe/Directly coupled/Directlv coupled |

| Feed rate | ||

| Cutting feed rate | m/min(inch/min) | 10(393.7) |

| Rapid on (X/Y/Z) axes | m/min(inch/min) | 48/48/48 |

| (X/Y/Z) fast moving speed | m/min(inch/min) | 1889.8/1889.8/1889.8 |

| Automatic tool changing system | ||

| Tool Type | type | BT40 |

| Tool capacity | set | Arm 24T |

| Maximum tool diameter | m(inch) | 80(3.1) |

| Maximum tool length | m(inch) | 300(11.8) |

| Maximum tool weight | kg(lbs) | 7(15.4) |

| Tool to tool change | sec | 3 |

| Motor | ||

| Spindle drive motor Contimious operation / 30 min rated |

(kw/hp) | MITSUBISH 5.5/7.5 (7.4/10.1) |

| Servo drive motor X, Y, Z axis | (kw/hp) | 2.0/2.0/3.0 (2.7/2.7/4) |

| Machine floor space and weight | ||

| Floor space | mm(inch) | 3400×2200×2800 (106.3×94.5×110.2) |

| Weight | kg(lbs) | 5000(11023.1) |

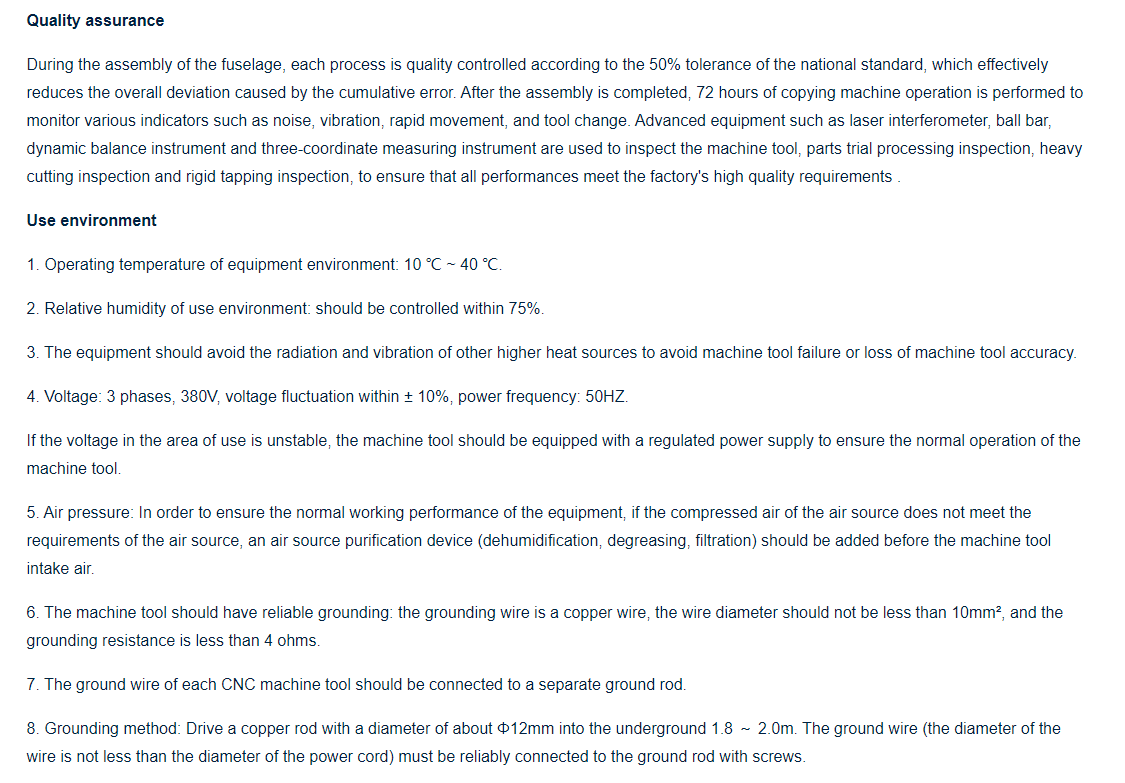

Transmission parts

German FAG, Japanese NSK precision bearings, Taiwan Intime or Shanghai Yin high-quality precision ball screws. The pre-stretching process is used to install the ball screw, which improves the rigidity of the transmission components and eliminates the elongation of the ball screw due to thermal stress during the temperature rise of the ball screw during operation.

Guide rails

The three axes adopt high-precision, high-speed, and high-load roller linear slide rails. The sliders are designed with longer and larger models to ensure static and dynamic accuracy, accuracy stability, and service life. The three axes all increase the guide rail span to maintain excellent dynamic and static accuracy during cutting. The Z axis adopts a design with no large torque and high power motor, which improves the mechanical response performance of the Z axis;

Lubrication

The lubricating oil circuit adopts a built-in design, and the guide rail and ball screw adopt a centralized automatic lubrication system, which can regularly and quantitatively inject oil into each lubricating part to ensure uniform lubrication of each moving surface, effectively reducing friction resistance and improving motion accuracy Ensure the service life of the guide rail and ball screw.

Machine tool protection

The machine tool is fully enclosed to ensure the personal safety of the workers during the process, and the coolant and iron filings during the process are safely and fully recovered to ensure a clean and tidy workplace. The machine tool guide rail adopts Taiwan stainless steel telescopic protective cover, which has the characteristics of good protection performance and long service life. It can effectively prevent iron filings and coolant from entering the machine tool and damage the guide rail and screw. The electric control box adopts a fully sealed design, and the heat exchanger performs heat dissipation, ensuring the cleanness of the electric control box and the service life of electrical components.

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Europe style for Edm Wire Cut Machine - Taiwan quality Chinese price MV855 Machine Center – BiGa , The product will supply to all over the world, such as: Latvia, Malta, Kuwait, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.