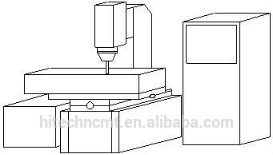

Factory best selling Orbit Head For Edm Die Sinker - Taiwan Ctek control BiGa ZNC 450 Die Sinking Machine Electronic Discharge Machine EDM – BiGa

Factory best selling Orbit Head For Edm Die Sinker - Taiwan Ctek control BiGa ZNC 450 Die Sinking Machine Electronic Discharge Machine EDM – BiGa Detail:

Product Application

EDM is also known as electric spark machining. It’s a direct utilization of electrical energy and heat processing technology. It is based on during the spark discharge between the tool and the workpiece for removing excess metal in order to achieve the dimension, shape and surface quality of the predetermined processing requirements

| Spec/Model | Bica 450 | Bica 540 | Bica 750/850 | Bica 1260 |

| CNC/ZNC | CNC/ZNC | CNC/ZNC | CNC | |

| Control of Z axis | CNC | CNC | CNC | CNC |

| size of work table | 700*400 mm | 800*400 mm | 1050*600 mm | 1250*800 mm |

| Travel of X axis | 450 mm | 500 mm | 700/800 mm | 1200mm |

| Travel of Y axis | 350 mm | 400 mm | 550/500 mm | 600 mm |

| Machine head stroke | 200 mm | 200 mm | 250/400 mm | 450mm |

| Max. table to quill distance | 450 mm | 580mm | 850 mm | 1000 mm |

| Max. weight of work piece | 1200 kg | 1500 kg | 2000 kg | 3500 kg |

| Max. electrode load | 120 kg | 150 kg | 200 kg | 300kg |

| Work tank size (L*W*H) | 1130*710*450 mm | 1300*720*475 mm | 1650*1100*630 mm | 2000*1300*700 mm |

| Fliter box capacity | 400 L | 460 L | 980 L | |

| Fliter box net weight | 150 kg | 180 kg | 300 kg | |

| Max. output current | 50 A | 75 A | 75 A | 75 A |

| Max. machining speed | 400 m³/min | 800 m³/min | 800 m³/min | 800 m³/min |

| Electrode wear ratio | 0.2%A | 0.25%A | 0.25%A | 0.25%A |

| Best surface finishing | 0.2 RAum | 0.2 RAum | 0.2 RAum | 0.2 RAum |

| Input power | 380V | 380V | 380V | 380V |

| output voltage | 280 V | 280 V | 280 V | 280 V |

| Controller weight | 350 kg | 350 kg | 350 kg | 350 kg |

| controller | Taiwan CTEK | Taiwan CTEK | Taiwan CTEK | Taiwan CTEK |

EDM Machine Details

EDM machine Parts Brand

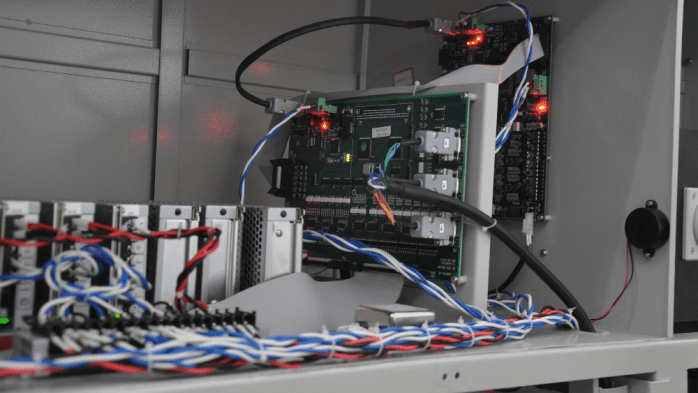

1.Control System:CTEK(Taiwan)

2.Z-axis motor:SANYO(Japan)

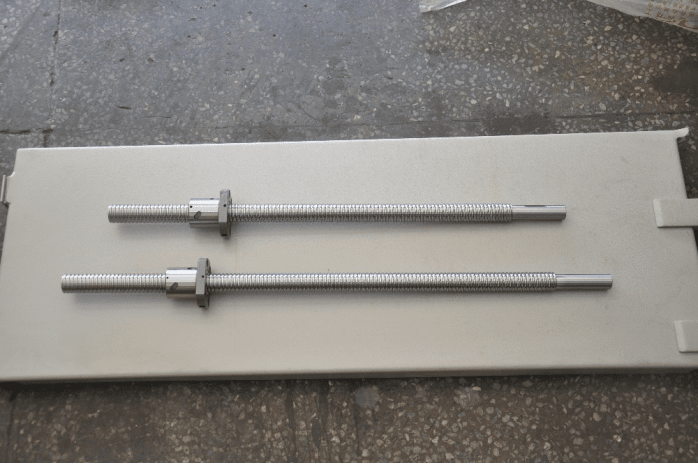

3.Three-axis ball screw:Shengzhang(Taiwan)

4.Bearing:ABM/NSK(Taiwan)

5.Pumping motor:Luokai(Incoporate)

6.Main contactor:Taian(Japan)

7.breaker:Mitsubishi(Japan)

8.Relay:Omron(Japan)

9.Switching power supply:Mingwei(Taiwan)

10.Wire (oil line):new light(Taiwan)

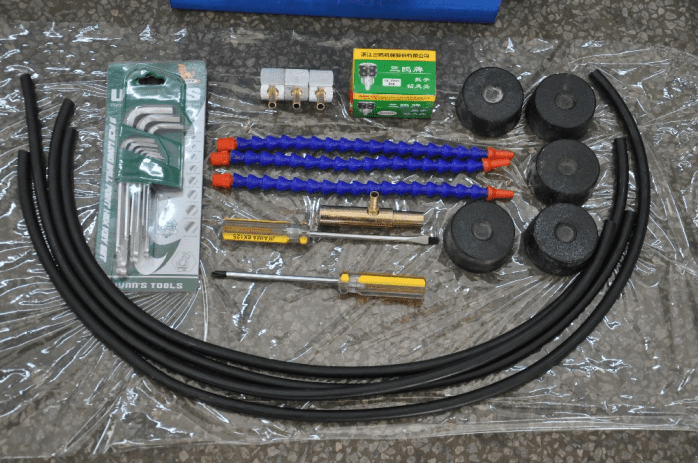

EDM Standard Accessories

Filter 2 pcs

Terminal Clamping 1 pcs

Injection Tube 4 pcs

Magnetic base 1 set

Allen key 1 set

Nuts 1 set

Tool box 1 set

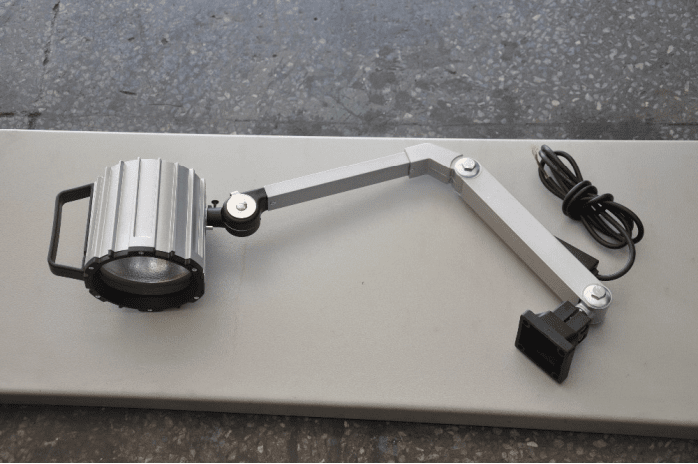

Quartz lamp 1 pcs

Extinguisher 1 pcs

Fixtures 1 set

Linear scale 3 pcs

Automatic call device 1 set

English user manual 1 pcs

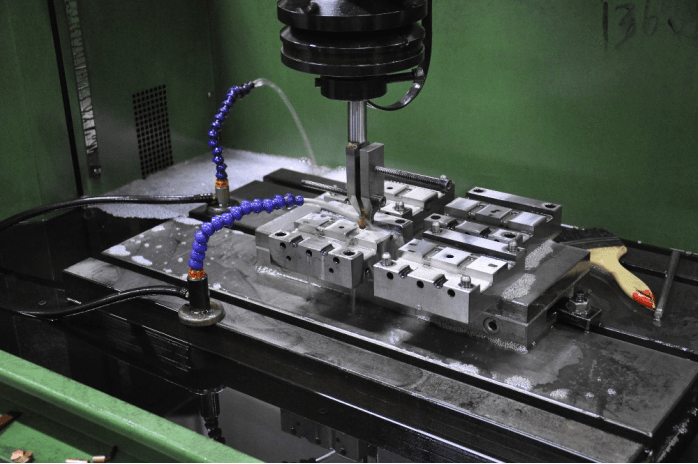

The EDM is made up of the main machine, working circulating fluid filtration system and power box. As shown in Figure 2.

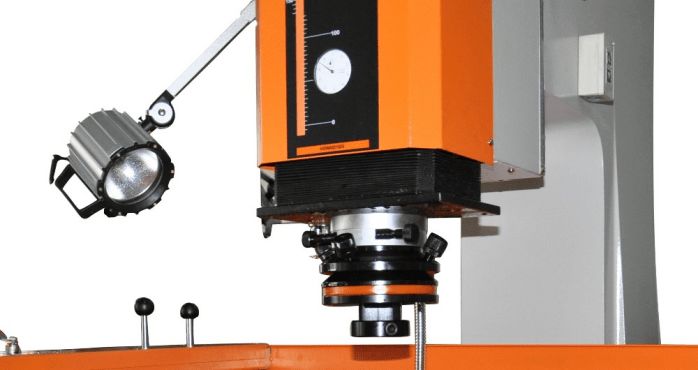

The main machine

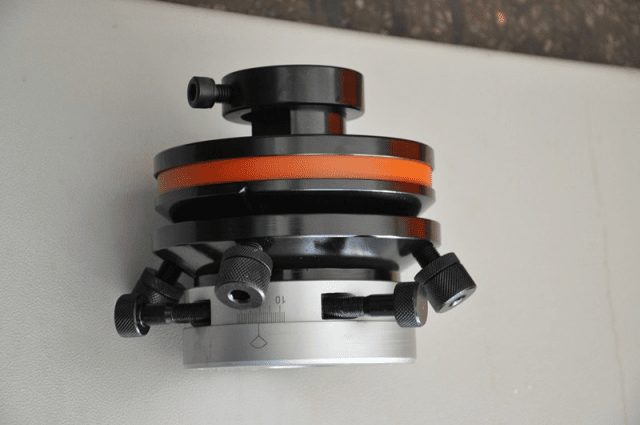

The main machine is used for supporting the tool electrode and workpiece to ensure their relative position, and the realization of the reliable feeding of electrode in the process. It is mainly composed of bed, carriage, worktable, column, upper drag plate, spindle head, clamp system, clamp system, lubrication system and transmission machine. The bed and column is basic structures, which make positioned between the electrode, worktable and the workpiece. The carriage and the worktable is used to support the workpiece, through the transmission system to adjust the relative position of the workpiece. The adjustment condition could be directly informed by the data from the display, transformed by the grating ruler. The drag plate on the column can be lifted and moved to adjust the tool electrode to the optimal location. The fixture system is a clamping tool for electrode, which is fixed on the spindle head. The spindle head is a key component of the electric spark forming machine.Its structure is composed of servo feed mechanism, guide, anti twisting mechanism and auxiliary mechanism. It controls the discharge gap between the workpiece and the tool.

Lubrication system is used to ensure the humidification state of the mutual movement faces.

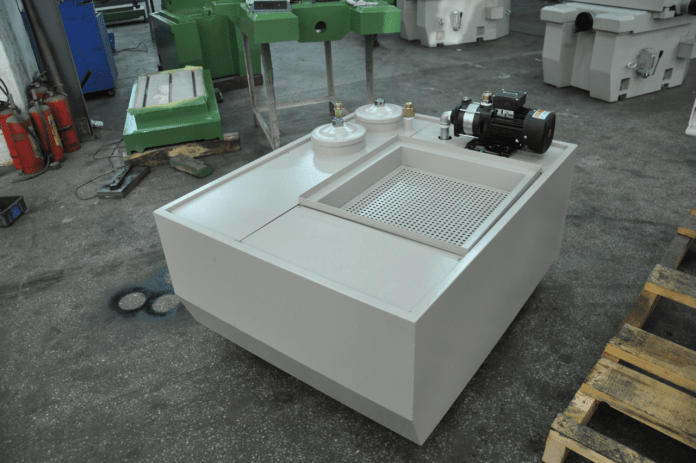

Working liquid circulation filtration system.

Working liquid circulation filtration system includes working liquid tank, liquid pumps, filters,pipeline, oil tank and some others. They make the forced working fluid circulation.

In the power box.

In the power box, the function of pulse power, which is exclusive for EDM processing, is to change industrial frequency exchanging current into one-way pulse current with certain frequency in order to supply the power to spark discharges for eroding metal. The pulse power has a great influence on technological and economic indicators, such as EDM processing productivity, surface quality, processing rate, processing stability and tool electrode loss. C

Packing & Delivery

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Factory best selling Orbit Head For Edm Die Sinker - Taiwan Ctek control BiGa ZNC 450 Die Sinking Machine Electronic Discharge Machine EDM – BiGa , The product will supply to all over the world, such as: Lyon, Iceland, Luxemburg, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.