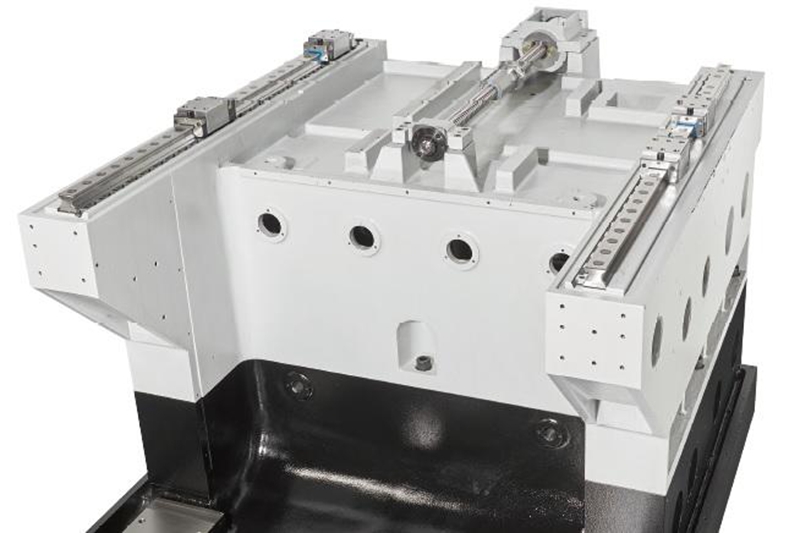

Microcut MCU-5X Vertical Machining Center

Features:

Rigid gantry design for geometrical precision and accurate dynamics

Specification:

| ITEM | UNIT | MCU |

| Rotary table top diameter | mm | ø600 ; ø500×420 |

| X / Y / Z axis travel | mm | 600 / 600 / 500 |

| Tilting axis A | degree | ±120 |

| Rotary axis C | degree | 360 |

| Max. weight on table | kg | 600 |

| Spindle speed range | rpm | In-line Spindle: |

| 15000rpm | ||

| Built-in Spindle: | ||

| 18000rpm(std)/24000rpm (opt) | ||

| Spindle motor output | kW | 25/35 (Siemens) |

| 20/25 (Built-in spindle) | ||

| Tooling fitting | BT40/DIN40/CAT40/HSK A63 | |

| ATC capacity (arm type) | 24(std.) / 32, 48, 60 (opt.) | |

| Max. tool length | mm | 300 |

| Max. tool dia. – adjacent stations empty | mm | 120 |

| Rapid feed rate X/Y/Z | m/min | 36 / 36 / 36 |

| Max. speed – axis A | rpm | 16.6 |

| Max. speed – axis C | rpm | 90 |

| Machine weight | kg | 9000 |

| Accuracy ( x/y/z axes) | ||

| Positioning | mm | 0.005 |

| Repeatability | mm | ±0.0025 |

Standard accessories:

Coolant through spindle with high pressure pump 20 bar (built-in type)

Rotary scales in A and C axis

Preparation for 3xHydraulic + 1xPnematic port

Chip conveyor and oil skimmer

TSC: Thermal spindle compensation

Optional parts:

Built-in spindle (18000/24000rpm)

Chain type ATC (32/48/60T)

Kinematics

Separate type tank with paper filter

Oil Mist Collector

Overhead roof

Automatic roof

Laser tool measurement integrated in table

Mechanical detachable tool setter

20/70 bar CTS with separate tank and paper filter

More 5-Axis series

Write your message here and send it to us