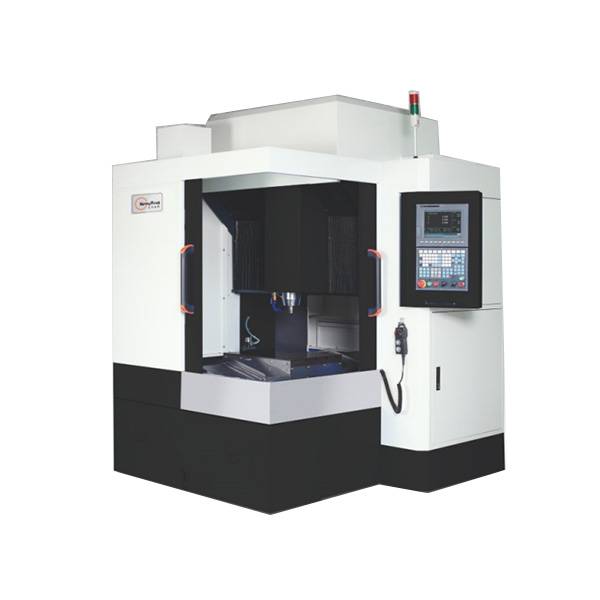

New Delivery for Znc Edm Machine - 650 Engraving and milling machine – BiGa

New Delivery for Znc Edm Machine - 650 Engraving and milling machine – BiGa Detail:

Mechanical characteristics

• The machine adopts the unique beam and bed integrated technology. Gantry type high rigidity structure. Ensure long-term high precision and service life of the machine, and strong shock resistance.

• The three-axis adopts imported high-precision linear guides and ball screws, which are wear-resistant, low friction coefficient, high positioning accuracy and flexibility, and stable movement. But it uses Japanese NSK bearings and imported couplings.

• The high-speed, high-torque, high-precision electric spindle can meet high-speed machining requirements and accuracy guarantee; it can realize high-speed ironing of small precision molds and parts, high machining accuracy, low vibration and low noise.

• The control system adopts Taiwan’s new generation, Baoyuan high-speed CNC system, which is easy to learn and use, and easy to master.

• The drive system adopts the AC drive servo system of Japan’s Yaskawa and Japan’s Sanyo, with stable operation, superior acceleration performance, low noise and high control accuracy.

| Models | unit | SH-650 |

| stroke | ||

| X axis travel | mm | 600 |

| Y axis travel | mm | 500 |

| Z axis travel | mm | 250 |

| Distance from work surface to spindle end surface | mm | 80-300 |

| Working tomb | ||

| Work size | mm | 600×500 |

| Maximum load | kg | 400 |

| Feed | ||

| Rapid feed | mm/min | 15000 |

| Cutting feed | mm/min | 1~8000 |

| Spindle | ||

| Spindle speed | r.p.m | 2000-24000 |

| Spindle dimension | ER25 | |

| The spindle cooling | Oil cooling | |

| Three axis servomotor | kw | 0.85-2.0 |

| Spindle motor | kw | 8.5 |

| other | ||

| The system configuration | The new generation,Bao yuan | |

| Resolution of NUMERICAL control system | mm | 0.001 |

| Positioning accuracy | mm | 0.005/300 |

| Repeat positioning accuracy | mm | ±0.003 |

| The knife instrument | The standard | |

| Lubrication system | Fully automatic lubrication system | |

| Machine weight | kg | 3100 |

| Mechanical dimensions | mm | 1730 ×1930 x2400 |

Product detail pictures:

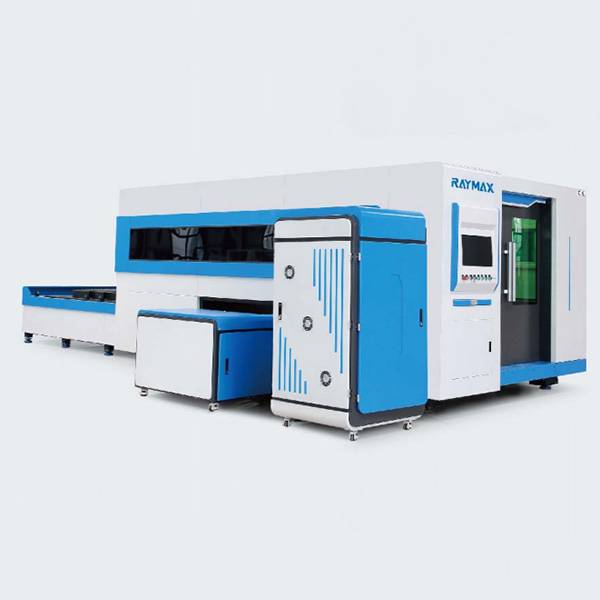

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for New Delivery for Znc Edm Machine - 650 Engraving and milling machine – BiGa , The product will supply to all over the world, such as: Sevilla, Dubai, Bangalore, For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.