Technical parameter of Hydraulic press brake with E21 125T/2500 mm

The Main feature

• The whole machine is in sheet plate welded structure, entire welded frame ,with internal stress eliminated by vibration aging technology ,high strength and good rigidity of machine.

• Double hydraulic oil cylinder is applied for upper transmission, provided with mechanical limit stopper and synchronous torsion bar, typical of stable and reliable operation, as well as high precision.

• Electrical control and manual fine-tuning mode are adopted for distance of rear stopper and stroke of gliding block ,and fitted with digital display device ,easy and quick in use.

• Slider stroke adjusting device and back gauge device: electric quick adjusting ,manual micro adjusting ,digital display ,easy and quick in use.

• The machine has inch, single, continuous mode specifications, commutation, dwell time can be controlled by time relay.

• Safety railing ,door-open power -off device.

• Mechanical synchrony torsion bar, to keep the left -right balance movement.

• Mechanical wedge partial compensation structure.

• Japan NOK original imported master cylinder seals.

Standard Equipment

Safety Standards(2006/42/EC):

1.EN 12622:2009 + A1:2013

2.EN ISO 12100:2010

3.EN 60204-1:2006+A1:2009

4.Front finger Protection(Safety light curtain)

5.South Korea Kacon Foot Switch(Level 4 of safety)

6.Back metal safe fence with CE standard

Hydraulic System

Hydraulic system is from Bosch -Rexroth, Germany.

When the oil comes out from the pump, all the way into the pressure cylinder first presses the sheet material, and another routing time relay controls the delay to enter the left cylinder upper chamber for about 2 seconds. The oil in the lower cylinder of the left cylinder is forced into the upper cylinder upper chamber and the right cylinder lower chamber. Oil back to the tank. The return stroke is reversed by the solenoid valve

Estun E21 Controller

• Numerical, one page programming

• Monochrome LCD Box Panel.

• Integral factor programmable freely

• Automatic positioning control

• Spindle allowance offset

• Internal time relay

• Stock counter

• Backgauge position display, resolution in 0.05mm

The technical parameter:

| Style | 125T/2500 mm | |

| Bend max length of the plate | mm |

2500 |

| Poles distance | mm |

1900 |

| Slipper stroke | mm |

120 |

| Max opening height | mm |

380 |

| Throat depth | mm |

320 |

| Table Width | mm |

180 |

| Working Height | mm |

970 |

| X Axis Speed | mm/s |

80 |

| Working Speed | mm/s |

10 |

| Return Speed | mm/s |

100 |

| Motor | kw |

7.5 |

| Voltage |

220V/380V 50HZ 3P |

|

| Oversize | mm |

2600*1750*2250 |

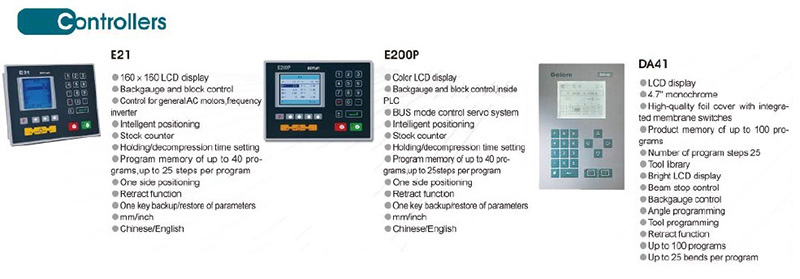

Optional controller

Main configuration

|

Part Name |

Brand |

Brand Origin |

|

Main Motor |

Siemens |

Germany |

|

Hydraulic Valve |

Rexroth |

Germany |

|

Main Electrics |

SCHNEIDER |

French |

|

NC Controller |

ESTUN E21 |

China |

|

Footswtich |

Karcon |

South Korea |

|

Limit Switch |

Schneider |

French |

|

Rolling Bearing |

SKF,NSK,FAG or INA |

Germany |

|

Front And Back Protection Fence |

Yes |

|

|

Emergency Button |

Yes |

|

|

Foundation Bolts |

1SET |

|