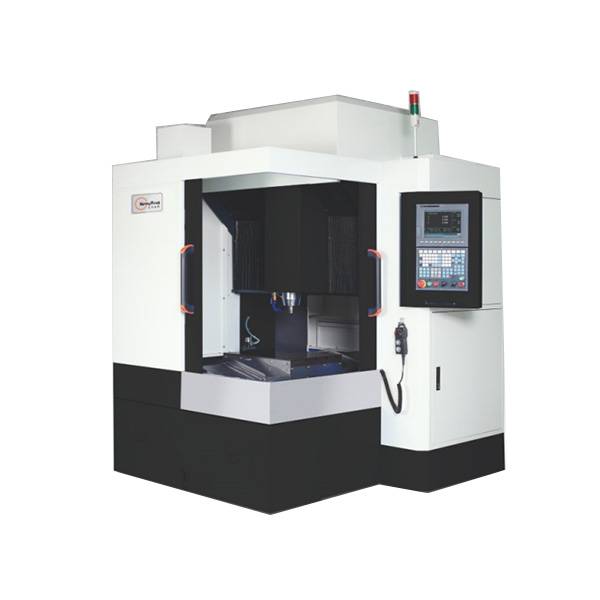

Well-designed Drill Edm - Hot Sale BiGa ZNC 450 High Quality Taiwan CTEK control Die Sinking Machine/ Die Sinker Electronic Discharge Machine EDM – BiGa

Well-designed Drill Edm - Hot Sale BiGa ZNC 450 High Quality Taiwan CTEK control Die Sinking Machine/ Die Sinker Electronic Discharge Machine EDM – BiGa Detail:

EDM is also known as electric spark machining/electric discharge machine. It’s a direct utilization of electrical energy and heat processing technology. It is based on during the spark discharge between the tool and the workpiece for removing excess metal in order to achieve the dimension, shape and surface quality of the predetermined processing requirements.

|

Spec/Model |

Bica 450 EDM

|

Bica 540 EDM | Bica 750 EDM |

| ZNC | ZNC | ZNC | |

|

Control of Z axis |

CNC | CNC | CNC |

|

size of work table |

700*400 mm | 800*400 mm | 1050*600 mm |

|

Travel of X axis |

450 mm | 500 mm | 700 mm |

|

Travel of Y axis |

350 mm | 400 mm | 500 mm |

|

Machine head stroke |

200 mm | 200 mm | 250 mm |

|

Max. table to quill distance |

450 mm | 580mm | 850 mm |

|

Max. weight of work piece |

1200 kg | 1500 kg | 2000 kg |

|

Max. electrode load |

120 kg | 150 kg | 200 kg |

|

Work tank size (L*W*H) |

1130*710*450 mm | 1300*720*475 mm | 1650*1100*630 mm |

|

Fliter box capacity |

400 L | 460 L | 980 L |

|

Fliter box net weight |

150 kg | 180 kg | 300 kg |

|

Max. output current |

50 A | 75 A | 75 A |

|

Max. machining speed |

400 m³/min | 800 m³/min | 800 m³/min |

|

Electrode wear ratio |

0.2%A | 0.25%A | 0.25%A |

|

Best surface finishing |

0.2 RAum | 0.2 RAum | 0.2 RAum |

|

Input power |

380V | 380V | 380V |

|

output voltage |

280 V | 280 V | 280 V |

|

Controller weight |

350 kg | 350 kg | 350 kg |

|

controller |

Taiwan CTEK | Taiwan CTEK | Taiwan CTEK |

Main Features

EDM is also known as electric spark machining. It’s a direct utilization of electrical energy and heat processing technology. It is based on during the spark discharge between the tool and the workpiece for removing excess metal in order to achieve the dimension, shape and surface quality of the predetermined processing requirements.

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Well-designed Drill Edm - Hot Sale BiGa ZNC 450 High Quality Taiwan CTEK control Die Sinking Machine/ Die Sinker Electronic Discharge Machine EDM – BiGa , The product will supply to all over the world, such as: India, Istanbul, New Zealand, We offer the great variety of products in this field. Besides, customized orders are also available. What's more, you will enjoy our excellent services. In one word, your satisfaction is guaranteed. Welcome to visit our company! For more information, please come to our website.If any further inquiries, please feel free to contact us.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.